| Stockcode | : | 661800 |

| Type | : | Drilling |

| Subtype | : | Miscellaneous |

| Manufacturer | : | FRANKLIN |

| Model | : | HD-145 |

| Year | : | 2001 |

| Price | : | P.O.A. |

| Description | : | |

|

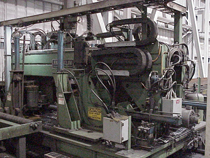

USED FRANKLIN CNC 3 SPINDLE STRUCTURAL DRILL SYSTEM

MODEL HD-145 ♦ YEAR: 2001 Stock No. W-1329 Specifications: Maximum beam width: 40 WF Beam feed rate in X-Axis (maximum): 100 FPM Rapid Advance (Web): 420 IPM Rapid Advance (Flanges): 420 IPM Retract speed (Web and Flanges): 420 IPM Spindle motors (AC Variable): 10 HP Motor capacities (Hydraulic): 3 @ 12 HP Drill feed rates (CNC controlled & monitored): 0-30 IPM Drill speeds: 0-1,800 RPM Drill capacity (Web): 1-9/16 (#4 Morse) Drill capacity (Flanges): 1-9/16 (#4 Morse) Equipped with: Thru Spindle Coolant Linear Transducer Position Feed Back ♦ (1)MAIN FRAME ASSEMBLY (Consisting of) - Heavy duty welded and machined with fixed bridge designed frame. -(3 EA) servo slides that support the Flange and Web Spindles. Servo slides are mounted on linear bearings, which are guided on four (4) THK rails with sealed bearings. -(2 EA) hydraulic side clamp assemblies, one on the infeed and one on the outfeed side of the drill. -(2 EA) hydraulic top clamp assemblies, one on the infeed and one on the outfeed side of the drill. -Slide clamps are self adjusting to individual section sizes automatically. ♦ (1)FRANKLIN HD-532-20 HP HYDRAULIC POWER UNIT Motor: 20 H.P. T.E.F.C. Spindle Feed: Hydraulic Servo Feed Position Movement System: Hydraulic Servo +/- .005 Absolute position for Z, Y, W Axis Oil Level: Indicator with Thermometer Oil Temperature: Heater with Thermostat Oil Cooler: Free standing (standard) Controls: Magnetic motor starters with fuse overloads ♦ (1) FRANKLIN MULTI-AXIS CNC CONTROL SYSTEM The Control System consists of two components a. Personal Computer (PC) b. Programmable Industrial Controller (PIC) These two components combined provide a highly reliable operating system, where each of the components performs its designed functions effectively. A. PERSONAL COMPUTER SYSTEM: - Hard drive - Microprocessor - 1 Parallel Port - Ram Memory - 2 Serial Ports - 14 Color Monitor - 3 ½ floppy drive - Interface Keyboard - The PC system is mounted in the operator panel along with the required system pushbuttons. - The computer system will meet or exceed the requirements for proper machine functions. The PC portion of the control package will perform a variety of functions based on the machine requirements. 1. Create and edit part programs. 2. Optimize parts into stock programs. 3. Display graphical representation of part program. 4. Mirror image of part program. 5. Run single part program. 6. Run single stock program. 7. Run multiple stock programs. 8. Run from last operation after abort. 9. Section table of material forms. 10. Diagnostics software (status of PLC variables and contacts). 11. Record part count and run time. 12. Machine setup and machine parameters. NOTE: Some of the above functions may not apply to all applications. B. PROGRAMMABLE INDUSTRIAL CONTROLLER SYSTEM: The PIC is a multi-axis integrated solution to the discrete logic & motion control found in todays industrial automation applications. The PIC will have exclusive control of all axis movement and processes. This is done through feedback of servo systems and hardwired inputs and outputs. The PIC is highlighted by some exclusive features such as: - 32 bit processor - Fast download - Acceleration and deceleration ramping - Full handshaking on the serial port - Modem compatible - Nonvolatile memory - Enclosed module packaging - Expandable memory - Serial communication The PC portion of the control package will perform a variety of functions based on the machine requirements. 1. Create and edit part programs. 2. Optimize parts into stock programs. 3. Display graphical representation of part program. 4. Mirror image of part program. 5. Run single part program. 6. Run single stock program. 7. Run multiple stock programs. 8. Run from last operation after abort. 9. Section table of material forms. 10. Diagnostics software (status of PLC variables and contacts). 11. Record part count and run time. 13. Machine setup and machine parameters. NOTE: Some of the above functions may not apply to all applications. 1 EA COOLANT SYSTEM for the high pressure mist coolant through the bit. Including tank and related components. - 20 gallon high capacity tanks - Rotating coupling - Mixing valve systems for variable coolant air distribution 1 EA DUAL AXIS PINCH ROLL DRIVE for infeed and outfeed measuring. - Maximum X axis speed .. 130 FPM - Infeed hydraulic pinch roll drive for measuring and driving the leading section of material. - Pressure switch material detection for side clamp to automatically find the width. - Vertical holddown rolls on both sides. - Precision measuring wheel for overall X axis length and hole location. - X Axis length accuracy .. +/- .030 - AC servo drive system synchronized with infeed/outfeed conveyors. - Outfeed pinch roll drive system for measuring and driving the trailing end of material complete with all above features. - Pinch roll clamps are self adjusting to individual section sizes automatically. | ||

| View all |

|

FRANKLIN (2) HD-145 (1) Drilling (102) Miscellaneous (282) |

United States

|  |